Cookies help us deliver our services. By using our services, you agree to our use of cookies.

Industrial Plant

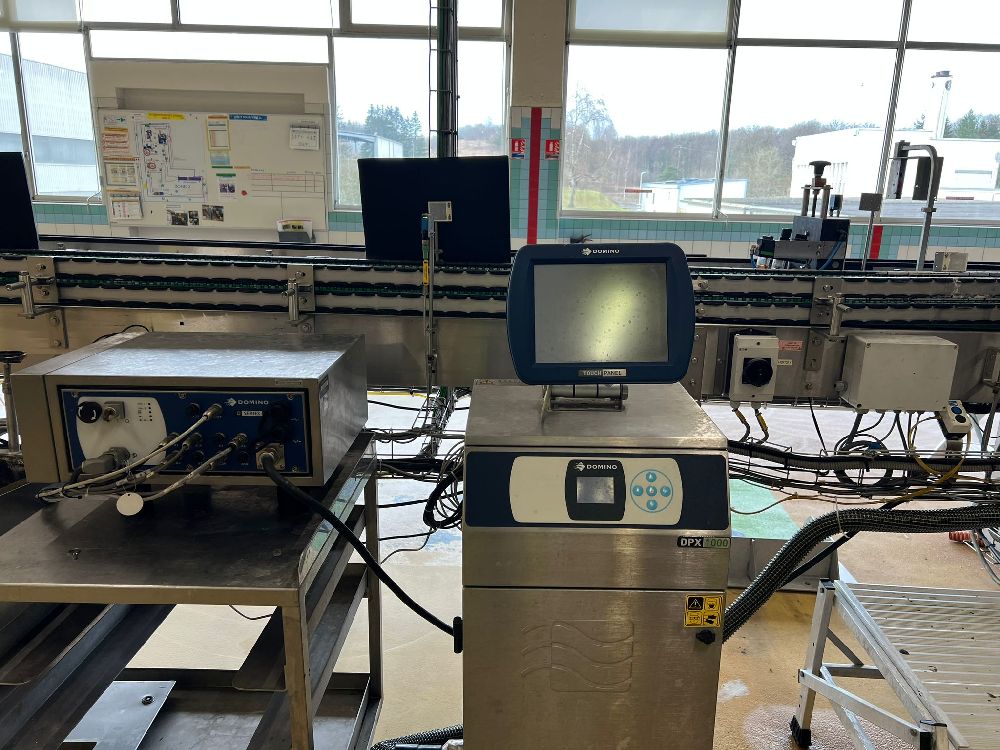

For Sale: State-of-the-Art TWIN Pack Mineral Water Bottling Plant

Elevate your beverage production with our premium TWIN Pack mineral water bottling facility, now available at an exceptionally competitive price. Installed in 2012 and meticulously maintained, this turnkey plant is in pristine condition and ready for immediate operation. In 2020, we upgraded the facility with a cutting-edge robotic palletizer, ensuring unparalleled efficiency and automation. Located in the heart of France, this facility is the perfect solution for businesses looking to scale their production capacity and streamline their bottling processes.

Why Choose the TWIN Pack Bottling Plant?

- High Production Capacity: Capable of producing 35,000 bottles per hour, this facility is designed to meet high-demand operations with ease.

- Versatile Bottle Compatibility: Seamlessly handles multiple bottle sizes, including 0.75L, 1L, and 1.5L, offering flexibility for various market needs.

- Impeccable Condition: Fully maintained since installation, with all equipment in excellent working order, ensuring reliability and minimal downtime.

- Modern Automation: Equipped with a 2020-installed robotic palletizer, enhancing productivity and reducing labor costs.

- Strategic Location: Situated in France, a hub for beverage production, providing logistical advantages for European and global markets.

- Turnkey Solution: Ready for immediate use, allowing you to start production without delays or additional investments.

This bottling plant is ideal for companies seeking to expand their operations, enter the mineral water market, or upgrade their existing facilities with state-of-the-art technology. Whether you're a large-scale producer or an emerging brand, the TWIN Pack plant offers the performance, reliability, and flexibility to drive your business forward.

Technical Specifications

- Production Capacity: 35,000 bottles per hour

- Bottle Sizes: Compatible with 0.75L, 1L, and 1.5L bottles

- Condition: Excellent, fully maintained, and operational

- Installation Year: 2012, with significant upgrades in 2020

- Location: France

- Power Requirements: 400 volts, 50 Hertz, 40 kW installed power

- Operating Pressure: 3.5 bar

Comprehensive Equipment List

The TWIN Pack bottling plant comes fully equipped with high-quality machinery, designed for precision, durability, and efficiency. Below is a detailed list of the included equipment:

- Preform Injector

- Model: Sameto Tachitelli ESH60205

- Serial Number: 1291501

- Year: 2003

- Description: High-precision injector for producing preforms, ensuring consistent quality and compatibility with various bottle sizes.

- Installed Power System

- Power: 40 kW

- Voltage: 400 volts, 50 Hertz

- Pressure: 3.5 bar

- Description: Robust power system designed to support the facility's high-capacity operations with energy efficiency.

- Bottle Blowing Machine

- Model: Sottile Sider SFT System, FT System H700-BK-FLY

- Serial Number: 12-346

- Voltage: 50 Hertz, 60 volts

- Description: Advanced blowing machine for producing high-quality PET bottles, optimized for speed and precision.

- Labeling Machine (Primary)

- Model: Tetra Pak Scoma SC-8B

- Serial Number: 1

- Year: 2014

- Description: High-speed labeling machine for accurate and professional label application, suitable for various bottle formats.

- Labeling Machine (Secondary)

- Model: Zalink Ecoline E230.01

- Serial Number: 1200834912

- Voltage: 230 volts, 50 Hertz

- Description: Complementary labeling system for enhanced flexibility and efficiency in label placement.

- Filling Machine

- Model: GEA Procomac Tralinox Titan-16K

- Serial Number: 1518

- Year: 2014

- Description: State-of-the-art filling machine with advanced technology for precise and hygienic filling of mineral water.

- Heat Shrink Tunnel

- Model: BFM

- Serial Number: 0254

- Year: 2014

- Description: Reliable heat shrink tunnel for secure and professional packaging of bottled products.

- Pneumatic Conveyor (2 Units)

- Model: Fanuc-Omni-Model 15-16 Series

-_neighbors: 2014 - Description: Dual pneumatic conveyors for seamless and efficient bottle transport throughout the production line.

- Conveyor Belt

- Model: Fanuc-Omni-Model 15-16 Series

- Year: 2014

- Description: High-capacity conveyor belt system designed for smooth and continuous operation.

- Cap Sorter

- Model: Krones Multivac Series

- Specifications: 400 Hertz, 50

- Year: 2014

- Description: Automated cap sorting system for fast and accurate cap placement, enhancing production efficiency.

Additional Features

- Robotic Palletizer (2020): Fully automated system for stacking and organizing pallets, reducing manual labor and increasing throughput.

- Comprehensive Maintenance Records: Detailed logs of all maintenance and upgrades, ensuring transparency and confidence in the facility's condition.

- Scalable Design: Modular setup allows for future expansions or modifications to meet evolving production demands.

Why Invest in This Bottling Plant?

The TWIN Pack mineral water bottling plant represents a rare opportunity to acquire a high-performance, fully equipped facility at a fraction of the cost of a new installation. With its modern equipment, robust production capacity, and excellent condition, this plant is poised to deliver immediate value to your business. Whether you're looking to boost your market presence or optimize your production processes, this facility offers the technology and reliability to achieve your goals.

Contact Us Today

Don’t miss this chance to own a world-class bottling plant. For more information, pricing details, or to schedule a viewing, please contact our team at [insert contact information]. Act now to secure this exceptional opportunity and take your beverage production to the next level!

.png)